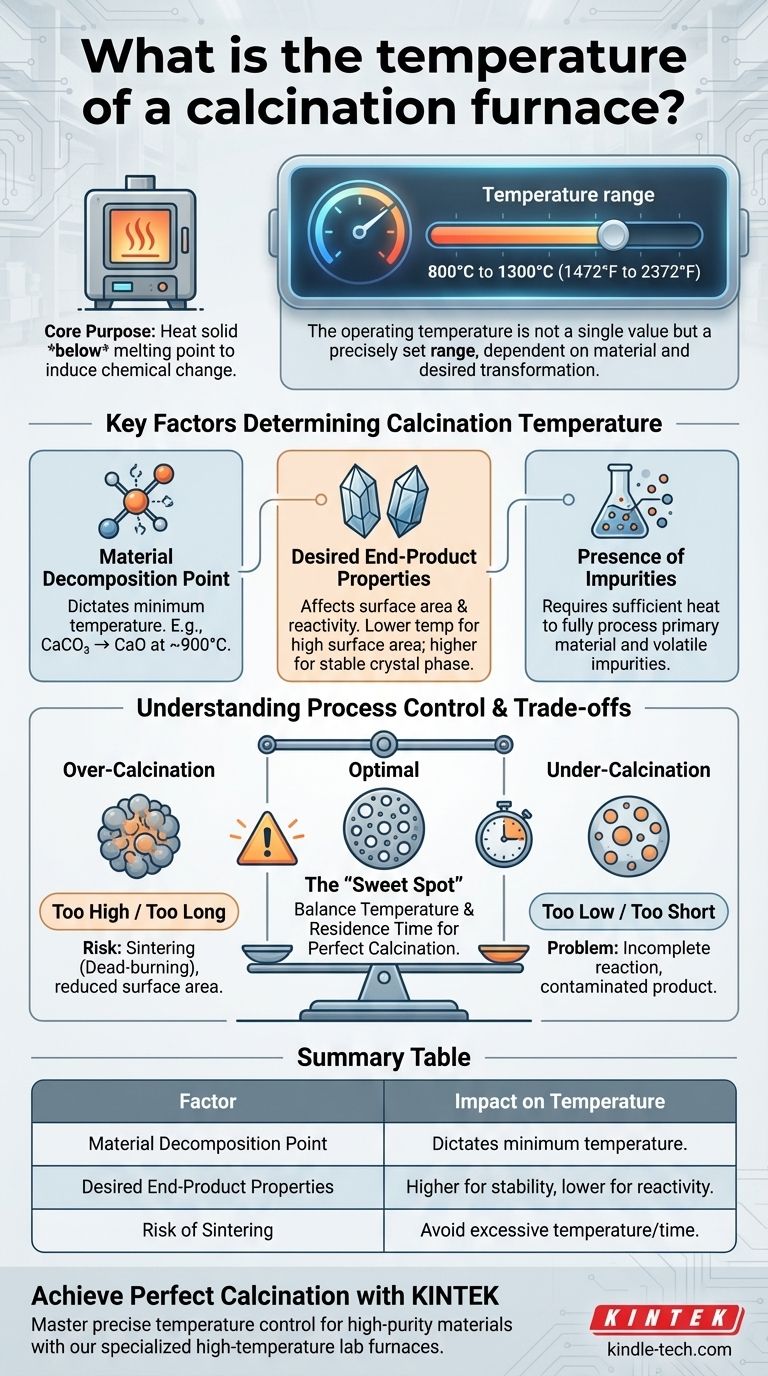

A temperatura operacional de um forno de calcinação não é um valor único, mas é definida com precisão dentro de uma faixa típica de 800°C a 1300°C (1472°F a 2372°F). Esta temperatura é cuidadosamente selecionada com base no material específico que está sendo processado e na transformação química ou física desejada.

O propósito central da calcinação é aquecer um material a uma temperatura específica abaixo do seu ponto de fusão para induzir uma mudança química. Portanto, a temperatura "correta" é ditada inteiramente pelo ponto de decomposição da substância e pelas propriedades desejadas no produto final.

O Que é Calcinação? Uma Introdução à Decomposição Térmica

A calcinação é um processo fundamental de tratamento térmico usado em indústrias como produção de cimento, processamento de minerais e fabricação de catalisadores. Compreender seus princípios centrais é fundamental para controlar o resultado.

O Princípio Central: Calor Sem Fusão

A característica definidora da calcinação é aquecer um material sólido a uma alta temperatura sem permitir que ele se funda ou derreta.

O objetivo é fornecer energia térmica suficiente para quebrar ligações químicas e desencadear uma reação, alterando fundamentalmente a composição do material.

Impulsionando a Mudança Química

A função primária da calcinação é causar a decomposição térmica. Isso geralmente envolve a remoção de um componente específico do material.

Exemplos comuns incluem:

- Remoção da água de cristalização (desidratação).

- Eliminação de dióxido de carbono (CO₂) de carbonatos, como a conversão de calcário em cal.

- Remoção de outros compostos orgânicos voláteis ou compostos de enxofre.

Alcançando a Transformação Física

Além da mudança química, a calcinação também é usada para alterar as propriedades físicas de um material.

Isso pode envolver a mudança da estrutura cristalina (transformação de fase) ou o aumento da porosidade e área de superfície de um material, o que é crucial para aplicações como catalisadores e adsorventes.

Fatores Chave que Determinam a Temperatura de Calcinação

A ampla faixa de 800°C a 1300°C existe porque diferentes materiais e objetivos exigem condições diferentes. A temperatura é uma variável cuidadosamente controlada, não uma configuração arbitrária.

Ponto de Decomposição do Material

Este é o fator mais crítico. Cada composto tem uma temperatura específica na qual se decompõe.

Por exemplo, o carbonato de cálcio (CaCO₃) começa a se decompor rapidamente em óxido de cálcio (CaO) e dióxido de carbono (CO₂) a aproximadamente 900°C. Para produzir cal, o forno deve operar a essa temperatura ou acima dela.

Propriedades Desejadas do Produto Final

Mesmo para o mesmo material, a temperatura final de calcinação afeta as propriedades do produto final.

Uma calcinação a uma temperatura mais baixa pode produzir um material com maior área de superfície e maior reatividade química. Inversamente, uma temperatura mais alta pode ser necessária para atingir uma fase cristalina específica e estável.

Presença de Impurezas

A composição da matéria-prima, incluindo quaisquer impurezas, pode influenciar a temperatura necessária. O processo deve fornecer calor suficiente para garantir que tanto o material principal quanto quaisquer impurezas voláteis indesejadas sejam totalmente processados.

Compreendendo as Compensações e o Controle do Processo

Alcançar a calcinação perfeita requer um equilíbrio delicado. Pequenos desvios de temperatura podem levar a problemas significativos com o produto final.

O Risco de Sobrecalcinação (Sinterização)

Se a temperatura for muito alta ou mantida por muito tempo, as partículas do material podem começar a se fundir em um processo chamado sinterização.

A sinterização reduz drasticamente a área de superfície e a reatividade do material, uma condição frequentemente chamada de "queima morta" (dead-burning). Este é um modo de falha comum que produz um produto de baixa qualidade ou inutilizável.

O Problema da Subcalcinação

Se a temperatura for muito baixa ou o tempo de processamento for muito curto, a reação química será incompleta.

Isso resulta em um produto final contaminado com o material de alimentação original não reagido, falhando em atender às especificações de pureza.

Temperatura vs. Tempo de Residência

A temperatura não é a única variável. A quantidade de tempo que o material passa na zona quente do forno, conhecida como tempo de residência, é igualmente importante.

Um processo pode atingir a calcinação completa em uma temperatura mais baixa usando um tempo de residência mais longo, o que às vezes pode ser uma estratégia para evitar a sinterização, garantindo uma reação completa.

Fazendo a Escolha Certa para o Seu Objetivo

Selecionar a temperatura ideal do forno é uma questão de definir seu objetivo de processo. Seu objetivo dita seus parâmetros operacionais.

- Se seu foco principal é produzir um material altamente reativo: Você provavelmente operará na extremidade inferior da faixa de decomposição do material para preservar a área de superfície máxima e evitar a sinterização.

- Se seu foco principal é garantir a decomposição completa e a pureza: Você pode precisar operar a uma temperatura moderada acima do ponto de decomposição, equilibrando a completude com o risco de sinterização.

- Se seu foco principal é atingir uma fase cristalina específica: A temperatura será ditada precisamente pela fase alvo, muitas vezes exigindo um controle muito rigoroso em um ponto específico dentro da faixa de calcinação.

Em última análise, dominar a calcinação reside em entender que a temperatura é a ferramenta que você usa para controlar precisamente a forma e a função final do seu material.

Tabela de Resumo:

| Fator | Impacto na Temperatura | Exemplo |

|---|---|---|

| Ponto de Decomposição do Material | Determina a temperatura mínima necessária para a reação. | CaCO₃ decompõe-se em CaO a ~900°C. |

| Propriedades Desejadas do Produto Final | Temperaturas mais altas podem reduzir a reatividade; temperaturas mais baixas preservam a área de superfície. | Um catalisador necessita de alta área de superfície (temperatura mais baixa). |

| Risco de Sinterização | Temperatura excessiva causa fusão das partículas, arruinando a qualidade do produto. | A sobrecalcinação leva à "queima morta". |

Alcance a Calcinação Perfeita com a KINTEK

Dominar o controle preciso da temperatura do seu processo de calcinação é fundamental para produzir materiais reativos e de alta pureza. Se você está desenvolvendo catalisadores, processando minerais ou fabricando cerâmicas avançadas, o forno certo faz toda a diferença.

A KINTEK é especializada em fornos de laboratório de alta temperatura projetados para aplicações exigentes de calcinação. Nosso equipamento oferece o aquecimento uniforme e o controle preciso de temperatura de que você precisa para evitar a subcalcinação e prevenir a sinterização destrutiva.

Deixe-nos ajudá-lo a otimizar seu processamento térmico:

- Selecione o forno certo para seu material específico e faixa de temperatura (800°C a 1300°C+).

- Garanta a decomposição completa e atinja suas fases cristalinas alvo.

- Melhore a qualidade e a consistência do seu produto com equipamentos confiáveis e duráveis.

Entre em contato com nossos especialistas em térmica hoje mesmo para discutir suas necessidades de calcinação e descobrir como as soluções da KINTEK podem aprimorar as capacidades do seu laboratório e impulsionar sua pesquisa.

Guia Visual

Produtos relacionados

- Máquina de Forno de Pirólise de Forno Rotativo Elétrico Calciner Forno Rotativo Pequeno

- Forno de Tubo de Laboratório de Alta Temperatura de 1400℃ com Tubo de Alumina

- Forno Rotativo Elétrico de Trabalho Contínuo, Pequeno Forno Rotativo, Planta de Pirólise de Aquecimento

- Forno Muffle de Laboratório com Muffle de Elevação Inferior

- Forno de Tubo de Alta Temperatura de Laboratório de 1700℃ com Tubo de Alumina

As pessoas também perguntam

- Que equipamento é usado na pirólise? Escolhendo o Reator Certo para sua Matéria-Prima e Produtos

- Quais são as aplicações industriais da pirólise? Transformar Resíduos em Energia e Produtos Valiosos

- Quais são os produtos da pirólise da madeira? Um Guia para Rendimentos de Biocarvão, Bio-óleo e Gás de Síntese

- Quais são as zonas do forno rotativo na produção de cimento? Domine o Processo Essencial para Clínquer de Alta Qualidade

- Que biomassa é usada na pirólise? Selecionando a matéria-prima ideal para seus objetivos