Visão geral dos fornos de mufla

Tipos e utilizações

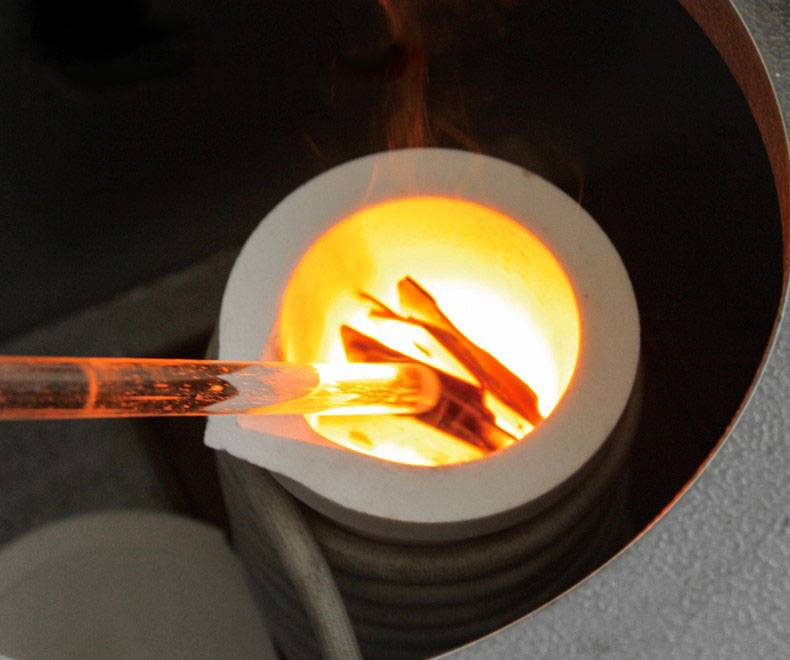

Os fornos de mufla, muitas vezes referidos como fornos de cinzas de alta temperatura, são equipamentos de aquecimento altamente versáteis que encontram aplicações num espetro de indústrias. Estes fornos são indispensáveis em processamento térmico Estes fornos são indispensáveis no processamento térmico, onde facilitam o aquecimento e arrefecimento controlados de materiais para obter transformações físicas e químicas específicas. No sector sector farmacêutico os fornos de mufla são utilizados em processos como a esterilização e a pirólise, garantindo a pureza e a eficácia dos medicamentos.

Na química analítica estes fornos desempenham um papel crucial na preparação de amostras, particularmente em técnicas como a incineração, em que os materiais orgânicos são convertidos em resíduos inorgânicos para análise posterior. Para análise da qualidade do carvão os fornos de mufla são utilizados para determinar o teor de cinzas e o valor calorífico de amostras de carvão, fornecendo dados críticos para a produção de energia e avaliações ambientais.

Sinterização de metais sinterização também beneficiam dos fornos de mufla, que ajudam a compactar os pós metálicos em formas sólidas com propriedades mecânicas melhoradas. Do mesmo modo, tratamento térmico utilizam estes fornos para alterar a microestrutura dos metais, melhorando assim a sua dureza, força e resistência ao desgaste.

No domínio da cozedura de cerâmica os fornos de mufla são essenciais para atingir as altas temperaturas necessárias para vitrificar a cerâmica, garantindo a sua durabilidade e qualidades estéticas. Por fim, na investigação experimental estes fornos oferecem um meio fiável de realizar experiências a alta temperatura, apoiando os avanços em várias disciplinas científicas.

Caraterísticas de desempenho

Os fornos de mufla são concebidos para fornecer uma gama de caraterísticas de desempenho que satisfazem diversas necessidades laboratoriais. Estes fornos são capazes de funcionar numa extensa gama de temperaturas, ultrapassando frequentemente os 1000°C, o que os torna adequados para aplicações de alta temperatura, como a cozedura de cerâmica e a sinterização de metais. As velocidades de aquecimento destes fornos são extraordinariamente rápidas, permitindo processos térmicos rápidos que podem reduzir significativamente os tempos de ciclo experimental.

O controlo preciso da temperatura é outra caraterística crítica, assegurando que o forno consegue manter temperaturas exactas, o que é essencial para experiências que exigem elevada precisão. Este nível de controlo é frequentemente conseguido através de sistemas avançados de controlo de temperatura que oferecem uma precisão de ±1°C ou superior, tornando-os ideais para química analítica e outras aplicações sensíveis.

Os volumes das câmaras dos fornos de mufla são personalizáveis, permitindo aos laboratórios selecionar o tamanho adequado com base nas suas necessidades específicas. Quer se trate de pequenas amostras ou de grandes lotes, a flexibilidade na conceção da câmara assegura que o forno pode acomodar várias configurações experimentais.

Alguns modelos avançados incluem câmaras de fibra cerâmica economizadoras de energia, que não só aumentam a eficiência do forno como também contribuem para a sua durabilidade. Estas câmaras foram concebidas para reter o calor de forma mais eficaz, reduzindo o consumo de energia e prolongando a vida útil do forno. Esta combinação de eficiência energética e durabilidade faz com que as câmaras de fibra cerâmica sejam a escolha preferida de muitos laboratórios.

Caraterísticas principais

Os fornos de mufla distinguem-se por várias caraterísticas-chave que os tornam adequados para uma variedade de aplicações laboratoriais e industriais. Estas caraterísticas não só melhoram a funcionalidade do forno, como também garantem a segurança e a eficiência no funcionamento.

Uma das caraterísticas de destaque é o corpo com design dividido que permite uma manutenção e reparação mais fáceis. Este design separa normalmente a câmara de aquecimento do painel de controlo, reduzindo o risco de perigos eléctricos e tornando mais simples a substituição de componentes como os elementos de aquecimento.

Controladores inteligentes são outro componente crítico, oferecendo automação e precisão avançadas. Estes controladores podem ser programados para gerir ciclos de aquecimento complexos, assegurando que o forno funciona dentro do intervalo de temperatura e duração desejados. Muitas vezes, são fornecidos com interfaces de fácil utilização, facilitando a configuração e a monitorização do forno, mesmo para operadores inexperientes.

Os elementos de aquecimento duradouros são essenciais para manter um desempenho consistente durante longos períodos. Estes elementos, muitas vezes feitos de materiais de alta qualidade como o carboneto de silício ou o dissiliceto de molibdénio, podem suportar temperaturas elevadas sem se degradarem, garantindo um aquecimento fiável e uma vida útil prolongada do forno.

Sistemas avançados de controlo da temperatura permitem uma regulação precisa da temperatura interna. Isto é crucial para experiências que requerem condições de temperatura exactas, tais como as da química analítica ou da ciência dos materiais. Muitos fornos modernos oferecem uma uniformidade de temperatura de ±1°C, o que é vital para resultados consistentes.

A segurança é uma preocupação primordial em ambientes laboratoriais, e os fornos de mufla estão equipados com várias caraterísticas de segurança . Estes podem incluir mecanismos de encerramento automático, alarmes de temperatura excessiva e botões de paragem de emergência, assegurando que o forno pode ser operado em segurança, mesmo em condições de falta de supervisão.

Finalmente, a capacidade de personalizar as câmaras do forno permite flexibilidade no manuseamento de diferentes tipos e tamanhos de amostras. Quer necessite de uma câmara pequena para análises de rotina ou de uma maior para processamento em massa, as opções personalizáveis garantem que o forno pode ser adaptado para satisfazer necessidades específicas.

Em resumo, a combinação destas caraterísticas torna os fornos de mufla uma escolha versátil e fiável para uma vasta gama de aplicações laboratoriais.

Seleção do forno de mufla adequado

Requisitos de temperatura

Ao selecionar um forno de mufla, é crucial considerar a gama de temperaturas necessária para as suas experiências específicas. Diferentes processos exigem temperaturas extremas variáveis, e compreender estas necessidades é essencial para escolher o equipamento correto.

Por exemplo, a secagem de materiais necessita tipicamente de temperaturas moderadas, geralmente entre 500 e 600°C. Esta gama garante que os materiais são secos de forma eficiente sem causar degradação térmica. Por outro lado, os processos de cozedura de cerâmica requerem frequentemente temperaturas muito mais elevadas, atingindo por vezes os 1700°C. Estas temperaturas elevadas são necessárias para obter as propriedades estruturais e físicas desejadas na cerâmica.

| Tipo de processo | Intervalo de temperatura | Importância do controlo da temperatura |

|---|---|---|

| Secagem de material | 500-600°C | Assegura uma secagem eficiente sem degradação térmica |

| Cozedura de cerâmica | Até 1700°C | Obtém as propriedades estruturais e físicas desejadas |

A compreensão destes requisitos de temperatura ajuda a selecionar uma mufla que possa satisfazer com precisão as necessidades térmicas das suas experiências, garantindo resultados óptimos e eficiência do processo.

Tamanho da câmara do forno

Ao selecionar um forno de mufla, o tamanho da câmara é uma consideração crítica que tem um impacto direto na eficiência e nos resultados das experiências. O tamanho da câmara deve ser compatível com o tamanho e o número de amostras que pretende processar. Amostras maiores, ou um maior volume de amostras, requerem uma câmara de forno maior para acomodar o espaço necessário para um aquecimento e processamento uniformes.

Para determinar o tamanho adequado da câmara, comece por avaliar as dimensões das suas amostras típicas. Considere se estas amostras são padrão ou invulgarmente grandes. Por exemplo, se trabalhar frequentemente com grandes peças de cerâmica ou com várias amostras em simultâneo, será indispensável uma câmara maior. Por outro lado, as câmaras mais pequenas são adequadas para amostras mais compactas ou individuais, optimizando o espaço e a eficiência energética.

Outro fator a considerar é o volume de amostras que processa regularmente. Requisitos de produção mais elevados podem necessitar de uma câmara maior para evitar recargas frequentes e para manter um funcionamento contínuo. Isto é particularmente importante em indústrias onde o processamento em lote é comum, como em laboratórios farmacêuticos ou de química analítica.

Em resumo, a escolha da dimensão da câmara do forno deve ser orientada pelas necessidades específicas do seu laboratório. Ao avaliar cuidadosamente o tamanho e o volume das suas amostras, pode selecionar uma mufla com uma câmara que garanta um desempenho e uma eficiência ideais nas suas experiências.

Uniformidade de temperatura

Para experiências precisas, é crucial selecionar um forno com elevada uniformidade de temperatura. Esta uniformidade é normalmente medida pela variação de temperatura na zona quente, frequentemente expressa como um intervalo (por exemplo, ±20°F). Por exemplo, os fornos em conformidade com a norma AMS 2750D, Classe 4, oferecem uma uniformidade de temperatura de ±20°F dentro do intervalo de 300-600°F. Este nível de precisão assegura que todas as amostras dentro da câmara do forno sofrem um aquecimento consistente, o que é essencial para resultados reproduzíveis.

No entanto, nem todas as aplicações requerem uma uniformidade tão rigorosa. A secagem de materiais em geral, por exemplo, pode não exigir o mesmo nível de precisão. Nestes casos, um forno com especificações de uniformidade de temperatura mais alargadas pode ser suficiente, reduzindo os custos sem comprometer a eficácia global do processo.

A uniformidade da temperatura num forno é largamente influenciada pela conceção da zona quente, incluindo o isolamento e a disposição dos elementos de aquecimento. A uniformidade óptima é conseguida através de um design cuidadoso que minimiza as lacunas e aberturas, particularmente em pontos críticos como as portas de saída de gás. Além disso, um sistema de aquecimento multi-zona pode ajudar a ajustar a potência de entrada de forma dinâmica, garantindo uma distribuição mais uniforme da temperatura em toda a câmara.

| Faixa de temperatura | Uniformidade (±°F) | Classe AMS 2750D |

|---|---|---|

| 300-600°F | 20 | Classe 4 |

| 600-900°F | 15 | Classe 3 |

| 900-2500°F | 10 | Classe 2 |

A compreensão destas especificações pode guiá-lo na escolha do forno correto para as necessidades específicas do seu laboratório, equilibrando precisão e praticidade.

Taxa de aumento de temperatura

Ao escolher uma mufla para as necessidades do seu laboratório, a taxa de aumento da temperatura é um fator crítico a considerar, especialmente para processos que requerem ciclos térmicos rápidos. Um forno com uma taxa de aumento de temperatura rápida pode reduzir significativamente o tempo necessário para atingir a temperatura de funcionamento desejada, acelerando assim os prazos experimentais e melhorando a eficiência global.

Para aplicações como a sinterização rápida ou tratamentos térmicos rápidos, é indispensável um forno capaz de atingir gradientes de temperatura elevados num curto período de tempo. Estes processos térmicos rápidos exigem equipamento que possa efetuar uma transição rápida da temperatura ambiente para a temperatura operacional, garantindo que as propriedades do material são alteradas dentro do período de tempo necessário.

No entanto, é importante notar que nem todos os processos laboratoriais necessitam de uma taxa de aumento rápido da temperatura. A sinterização de rotina, por exemplo, pode não exigir esta caraterística, uma vez que envolve frequentemente um aquecimento prolongado a uma temperatura constante. Nesses casos, um forno com uma taxa de aumento de temperatura mais moderada pode ser suficiente, equilibrando o desempenho com a relação custo-eficácia.

| Tipo de processo | Requisitos de taxa de subida de temperatura |

|---|---|

| Processos térmicos rápidos | Elevada (aumento rápido da temperatura) |

| Sinterização de rotina | Moderada (aumento constante da temperatura) |

Em resumo, embora uma taxa de aumento rápido da temperatura possa ser um fator de mudança para determinadas aplicações laboratoriais, não é universalmente essencial. Uma análise cuidadosa das suas necessidades experimentais específicas ajudá-lo-á a determinar o equilíbrio ideal entre velocidade e custo.

Precisão de controlo

Para experiências que requerem um controlo exato da temperatura, é imperativo selecionar fornos com elevada precisão, tipicamente com ±1°C ou melhor. Este nível de precisão garante que as condições térmicas permanecem consistentes e dentro dos parâmetros desejados, o que é crucial para experiências que envolvem materiais sensíveis ou reacções químicas precisas.

| Nível de precisão | Aplicações típicas |

|---|---|

| ±1°C ou melhor | Química analítica, investigação farmacêutica e estudos experimentais que requerem um controlo exato da temperatura. |

| ±5°C ou superior | Tratamentos gerais de aquecimento, secagem de materiais e processos de sinterização de rotina. |

Em contraste, os tratamentos gerais de aquecimento, como a secagem de materiais ou a sinterização de rotina, podem não necessitar de uma precisão tão rigorosa. Estes processos toleram frequentemente uma gama mais ampla de variabilidade de temperatura, tornando os fornos com um controlo menos preciso suficientes para as suas necessidades. Por conseguinte, a escolha do forno deve estar alinhada com os requisitos específicos da experiência para garantir eficiência e exatidão.

Material do forno

Ao selecionar um forno de mufla, o material da lareira é um fator crítico que influencia diretamente o desempenho e a longevidade do forno. Os dois materiais primários utilizados para as lareiras são a fibra cerâmica e o tijolo refratário, cada um oferecendo vantagens distintas adaptadas a diferentes aplicações.

Os fornos de fibra cerâmica são conhecidos pelas suas capacidades de aquecimento rápido e eficiência energética. Estas lareiras são compostas por materiais leves e isolantes que permitem mudanças rápidas de temperatura, tornando-as ideais para processos que requerem ciclos de aquecimento frequentes ou rápidos. A sua conceção eficiente em termos energéticos ajuda a reduzir os custos operacionais, o que é particularmente benéfico para os laboratórios onde o consumo de energia é uma preocupação fundamental.

Por outro lado, as lareiras de tijolo refratário são construídas para resistir a temperaturas extremas e são mais duradouras para aplicações de alta temperatura. Estes fornos são construídos com materiais que podem suportar uma exposição prolongada a altas temperaturas sem se degradarem, o que os torna adequados para operações que exigem um processamento contínuo a altas temperaturas, como a cozedura de cerâmica ou a sinterização de metais. Embora possam demorar mais tempo a aquecer em comparação com as placas de fibra cerâmica, a sua durabilidade superior garante uma vida útil mais longa e um desempenho consistente em condições exigentes.

A escolha entre estes materiais depende dos requisitos específicos dos seus processos laboratoriais. Para experiências que requerem um aquecimento rápido e eficiência energética, as placas de fibra cerâmica são a escolha preferida. No entanto, para aplicações que envolvam operações contínuas a altas temperaturas, as placas de tijolo refratário oferecem a robustez e a fiabilidade necessárias.

Caraterísticas adicionais

Ao selecionar um forno de mufla, é crucial considerar as caraterísticas que podem melhorar a funcionalidade e a eficiência das suas experiências. Controlos programáveis são particularmente benéficos para experiências que requerem tratamentos térmicos precisos e em várias fases. Estes controlos permitem a personalização de perfis de aquecimento, assegurando que cada fase do processo é executada de forma precisa e consistente.

Os alarmes automáticos são outra caraterística essencial, fornecendo notificações em tempo real para eventos críticos, como atingir uma temperatura específica, flutuações de energia ou avarias do sistema. Isto garante que pode resolver prontamente quaisquer problemas, minimizando o risco de erros experimentais ou danos no equipamento.

Para experiências que envolvam materiais sensíveis ou processos de tempo crítico caraterísticas como monitorização remota e registo de dados podem ser inestimáveis. Estas capacidades permitem-lhe acompanhar e registar dados de temperatura ao longo do tempo, fornecendo informações valiosas sobre o desempenho do seu forno e os resultados das suas experiências.

Além disso, considere fornos equipados com tecnologias de poupança de energia tais como câmaras de fibra cerâmica que oferecem tempos de aquecimento mais rápidos e um menor consumo de energia em comparação com as tradicionais lareiras de tijolo refratário. Estas caraterísticas não só reduzem os custos operacionais, como também contribuem para um ambiente laboratorial mais sustentável.

Avaliando cuidadosamente estas caraterísticas adicionais, pode selecionar uma mufla que não só satisfaça as suas necessidades experimentais, como também aumente a eficiência e eficácia globais do seu trabalho laboratorial.

Produtos relacionados

- Forno de Mufla de 1200℃ para Laboratório

- Forno de Mufla de 1700℃ para Laboratório

- Forno Muffle de 1400℃ para Laboratório

- Forno de Mufla de 1800℃ para Laboratório

- Crisol Cerâmico Avançado de Alumina Fina de Engenharia Al2O3 para Forno de Mufla de Laboratório

Artigos relacionados

- Fornos de laboratório avançados: Opções de caixa, mufla e tubo para aplicações de alta temperatura

- O guia definitivo para escolher o forno de laboratório certo para as suas necessidades

- Forno de mufla: desvendando os segredos do aquecimento uniforme e da atmosfera controlada

- Guia completo sobre fornos de mufla: Tipos, usos e manutenção

- Comparação de características e especificações de fornos de laboratório: Um guia