Em sua essência, o sputtering de magnetron pulsado é uma técnica avançada de deposição física de vapor (PVD) que resolve um problema crítico encontrado no sputtering DC padrão: a deposição instável de materiais isolantes ou dielétricos. Ele funciona aplicando energia ao alvo de sputtering em pulsos curtos e controlados, em vez de uma corrente contínua. Este mecanismo de pulsação impede os arcos elétricos destrutivos que, de outra forma, se formariam em um alvo isolante, permitindo a criação de filmes finos de cerâmica e compostos de alta qualidade com excelente estabilidade e controle.

O sputtering pulsado não é um processo fundamentalmente diferente, mas sim uma evolução crucial. Ele combina as altas taxas de deposição do sputtering DC com a versatilidade de material do sputtering de RF, oferecendo uma solução moderna e superior para depositar filmes finos isolantes de alto desempenho.

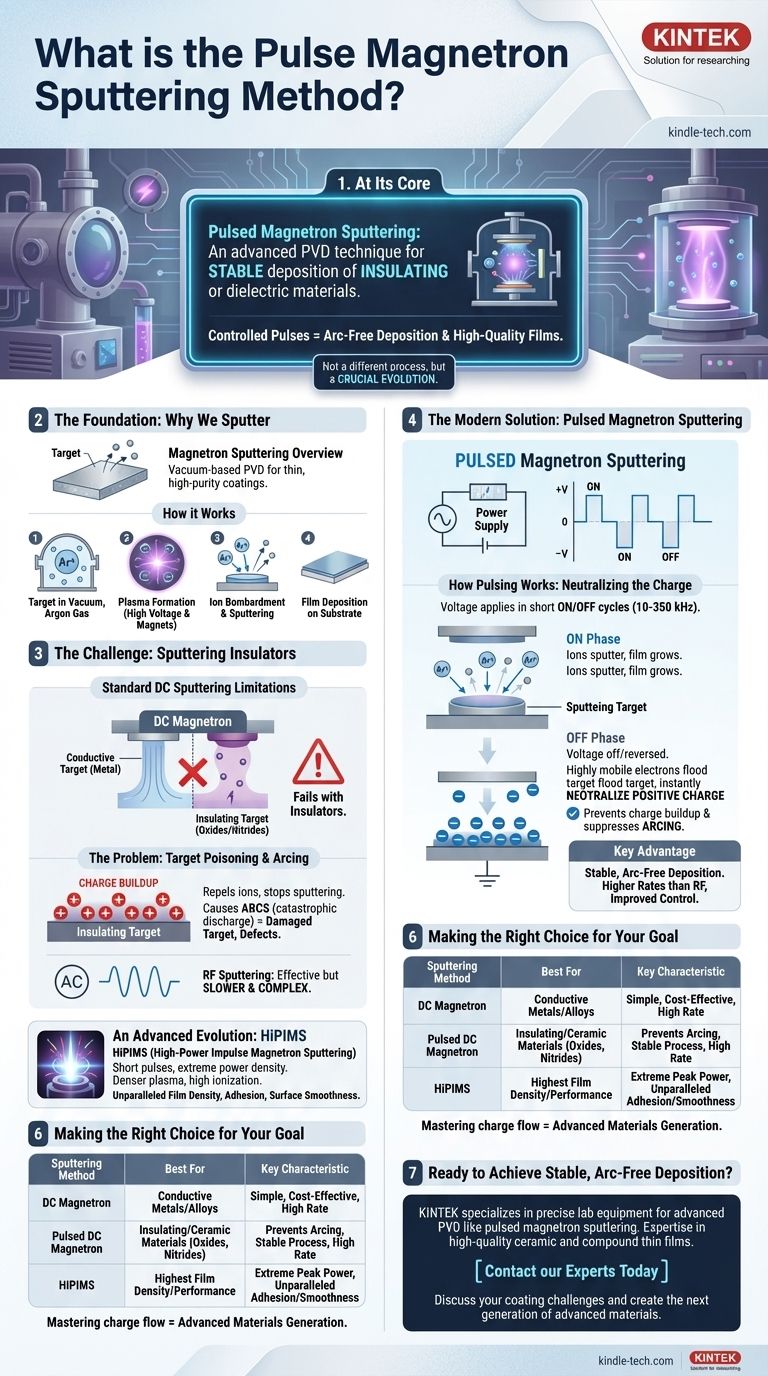

A Fundação: Por Que Fazemos Sputtering

O sputtering de magnetron é um processo baseado a vácuo usado para depositar revestimentos excepcionalmente finos e de alta pureza em um substrato. É valorizado por sua capacidade de criar filmes com adesão e uniformidade superiores em comparação com outros métodos, como a evaporação térmica.

Como Funciona o Sputtering de Magnetron

O processo começa com uma placa sólida do material de revestimento, conhecida como alvo. Este alvo é colocado em uma câmara de vácuo, que é então preenchida com um gás inerte, tipicamente Argônio.

Uma alta tensão é aplicada ao alvo, fazendo com que o gás se ionize e forme um plasma. Um campo magnético poderoso atrás do alvo aprisiona elétrons perto de sua superfície, aumentando drasticamente a eficiência do processo de ionização.

Íons de Argônio carregados positivamente são acelerados pelo campo elétrico e colidem com o alvo carregado negativamente. Essas colisões de alta energia expulsam fisicamente, ou "pulverizam" (sputter), átomos do material alvo. Esses átomos pulverizados viajam através do vácuo e se depositam em um substrato, construindo uma camada de filme fino, camada por camada.

O Poder dos Filmes Pulverizados (Sputtered)

Os átomos ejetados de um alvo pulverizado têm energia cinética significativamente maior do que aqueles de uma fonte evaporada. Essa alta energia resulta em filmes que são mais densos e têm muito melhor adesão ao substrato.

Além disso, o sputtering pode depositar virtualmente qualquer material, incluindo ligas, compostos e elementos com pontos de fusão extremamente altos, tudo isso sem a necessidade de derreter o material fonte.

O Desafio: Pulverizar Materiais Isolantes

Embora o sputtering DC (Corrente Contínua) padrão seja altamente eficaz para alvos metálicos condutores, ele falha ao tentar depositar materiais eletricamente isolantes, como óxidos ou nitretos.

O Problema com o DC: Envenenamento do Alvo e Arcos

No sputtering DC, o alvo é mantido em uma tensão negativa constante para atrair os íons de Argônio positivos. Se o alvo for um isolante, esses íons positivos se acumulam em sua superfície porque a carga não tem para onde ir.

Esse acúmulo de carga positiva, às vezes chamado de "envenenamento do alvo", eventualmente repele os íons de Argônio que se aproximam, retardando ou interrompendo o processo de sputtering. Pior ainda, pode levar a uma descarga catastrófica e repentina de energia conhecida como arco, que pode danificar o alvo e lançar detritos no filme em crescimento, criando defeitos.

A Solução Tradicional: Sputtering de RF

A solução clássica para este problema era usar uma fonte de alimentação de Radiofrequência (RF) em vez de uma DC. A tensão CA rapidamente alternada atrai alternadamente íons (para pulverizar) e, em seguida, elétrons (para neutralizar o acúmulo de carga).

Embora eficaz, o sputtering de RF tem desvantagens significativas. Geralmente, tem uma taxa de deposição muito menor do que o sputtering DC e requer fontes de alimentação complexas e caras com redes de casamento de impedância, tornando o processo menos eficiente e mais difícil de controlar.

A Solução Moderna: Sputtering de Magnetron Pulsado

O sputtering pulsado foi desenvolvido para superar as limitações dos métodos DC e RF, oferecendo uma maneira robusta e eficiente de depositar filmes isolantes.

Como Funciona a Pulsação: Neutralizando a Carga

Em vez de uma tensão DC contínua, uma fonte de alimentação pulsada aplica tensão em uma série de ciclos curtos de ligado/desligado em uma frequência de faixa média (tipicamente 10-350 kHz).

Durante a fase "ligada" mais longa, o alvo pulveriza como em um processo DC. Durante a fase "desligada" muito breve, a tensão é desligada ou revertida para ser ligeiramente positiva. Isso atrai uma enxurrada de elétrons altamente móveis do plasma, que neutralizam instantaneamente a carga positiva acumulada na superfície do alvo.

A Vantagem Chave: Deposição Estável e Livre de Arcos

Este simples ciclo liga/desliga impede eficazmente o acúmulo de carga e suprime a formação de arcos antes que ela possa começar. Isso leva a um processo extremamente estável e repetível, capaz de produzir filmes isolantes de alta qualidade e sem defeitos.

As taxas de deposição são tipicamente muito maiores do que no sputtering de RF, e o controle do processo é significativamente melhorado.

Uma Evolução Avançada: HiPIMS

Uma forma especializada desta técnica é o Sputtering de Magnetron de Impulso de Alta Potência (HiPIMS). O HiPIMS usa pulsos muito curtos com densidades de potência de pico extremamente altas. Isso cria um plasma muito mais denso com um alto grau de ionização, resultando em filmes pulverizados com densidade, adesão e suavidade de superfície incomparáveis.

Fazendo a Escolha Certa para o Seu Objetivo

Compreender o papel da pulsação permite que você selecione a tecnologia de sputtering ideal para sua aplicação específica.

- Se o seu foco principal são filmes condutores simples: O sputtering de magnetron DC padrão é o método mais direto e econômico para depositar metais puros e ligas condutoras.

- Se o seu foco principal é a deposição de materiais isolantes ou cerâmicos: O sputtering de magnetron DC pulsado é o padrão moderno da indústria, fornecendo deposição estável e de alta taxa de materiais como óxidos, nitretos e outros dielétricos.

- Se o seu foco principal é alcançar a maior densidade e desempenho de filme possíveis: O HiPIMS é a tecnologia superior, embora mais complexa, para criar revestimentos avançados onde a perfeição estrutural é fundamental.

Ao dominar o fluxo de carga na superfície do alvo, o sputtering pulsado capacita engenheiros e cientistas a criar uma nova geração de materiais avançados.

Tabela de Resumo:

| Método de Sputtering | Melhor Para | Característica Chave |

|---|---|---|

| Magnetron DC | Metais/ligas condutoras | Simples, econômico, alta taxa de deposição |

| Magnetron DC Pulsado | Materiais isolantes/cerâmicos (óxidos, nitretos) | Previne arcos, processo estável, alta taxa |

| HiPIMS | Maior densidade/desempenho do filme | Potência de pico extrema, adesão/suavidade incomparáveis |

Pronto para alcançar deposição estável e livre de arcos dos seus filmes isolantes avançados?

A KINTEK é especializada em fornecer os equipamentos de laboratório precisos e consumíveis que você precisa para processos PVD avançados, como o sputtering de magnetron pulsado. Nossa experiência garante que você obtenha a solução certa para depositar filmes finos de cerâmica e compostos de alta qualidade com excelente controle e estabilidade.

Contate nossos especialistas hoje para discutir como podemos apoiar os desafios específicos de revestimento do seu laboratório e ajudá-lo a criar a próxima geração de materiais avançados.

Guia Visual

Produtos relacionados

- Sistema RF PECVD Deposição Química de Vapor Aprimorada por Plasma de Radiofrequência RF PECVD

- Equipamento de Forno Tubular de Deposição Química de Vapor Aprimorada por Plasma Inclinado PECVD

- Barco de Evaporação para Matéria Orgânica

- Sistema de Câmara de Deposição Química em Fase Vapor CVD Forno de Tubo PECVD com Gaseificador Líquido Máquina PECVD

- Potenciostato de Estação de Trabalho Eletroquímico para Uso Laboratorial

As pessoas também perguntam

- O que é o método de deposição química de vapor ativada por plasma? Uma solução de baixa temperatura para revestimentos avançados

- O que é deposição química a vapor ativada por plasma? Permite a deposição de filmes finos a baixas temperaturas

- Como a energia RF cria plasma? Obtenha Plasma Estável e de Alta Densidade para Suas Aplicações

- Qual é o princípio da deposição química a vapor assistida por plasma? Obtenha Deposição de Filmes Finos em Baixa Temperatura

- Qual é a velocidade do PECVD? Obtenha Deposição de Alta Velocidade e Baixa Temperatura para o Seu Laboratório