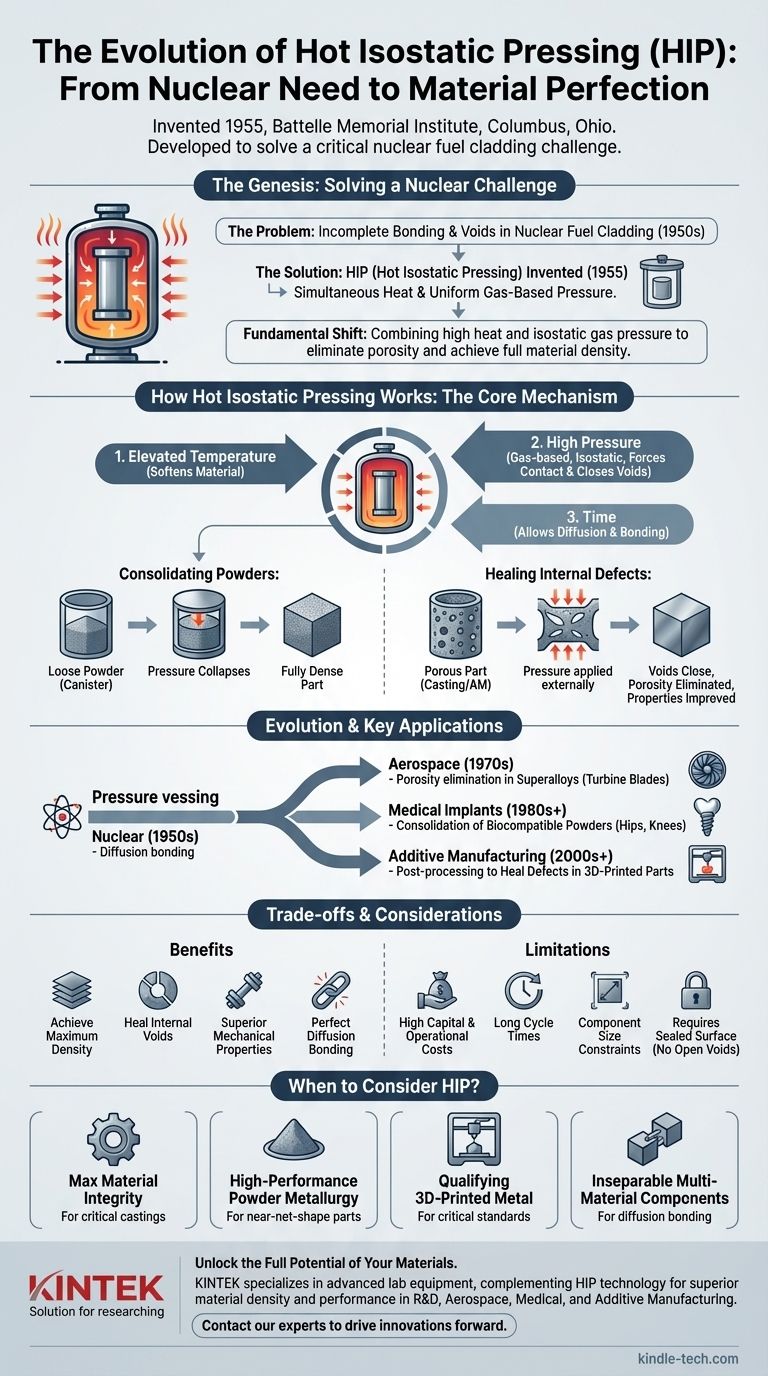

Inventada em meados da década de 1950, a Prensagem Isostática a Quente (HIP) foi formalmente desenvolvida em 1955 por pesquisadores do Battelle Memorial Institute em Columbus, Ohio. A tecnologia não foi criada para a fabricação de uso geral, mas para resolver um desafio altamente específico e crítico na indústria nuclear: a soldagem por difusão de um revestimento protetor em elementos de combustível nuclear.

A invenção da Prensagem Isostática a Quente foi uma mudança fundamental no processamento de materiais. Ao combinar calor elevado com pressão uniforme baseada em gás, ela possibilitou eliminar a porosidade interna e atingir a densidade total do material, criando peças com propriedades mecânicas superiores que eram anteriormente inatingíveis.

A Gênese da HIP: Resolvendo um Desafio Nuclear

O problema original que a HIP foi projetada para resolver era de extrema consequência. Em um reator nuclear, o contato perfeito entre o combustível de urânio e seu revestimento protetor é essencial para a transferência eficiente de calor e segurança.

O Problema da Ligação Incompleta

Os métodos tradicionais de ligação ou revestimento de materiais frequentemente deixavam vazios microscópicos ou áreas de contato incompleto. Em um ambiente nuclear, essas pequenas lacunas inibiriam a transferência de calor, levando a pontos quentes perigosos e potencial falha do combustível.

A Inovação da Battelle

A equipe da Battelle concebeu uma nova abordagem. Eles propuseram colocar os componentes dentro de um vaso selado, aquecê-los a uma alta temperatura abaixo de seu ponto de fusão e, simultaneamente, pressurizar o vaso com um gás inerte de alta pressão.

O Avanço "Isostático"

A chave foi usar um gás (tipicamente Argônio) como meio de transmissão de pressão. Diferentemente de uma prensa mecânica, que aplica força em uma direção, o gás exercia pressão uniforme, ou "isostática," sobre o componente de todas as direções. Isso forçou os dois materiais a um contato íntimo, átomo a átomo, criando uma ligação metalúrgica perfeita, livre de quaisquer vazios.

Como a Prensagem Isostática a Quente Funciona Fundamentalmente

O processo é uma interação precisa de três parâmetros críticos, cada um controlado dentro de um vaso de pressão especializado. Essa combinação é o que permite que a HIP altere fundamentalmente a estrutura interna de um material.

Os Três Parâmetros Chave

O cerne do processo HIP é a aplicação simultânea de temperatura elevada, alta pressão e tempo. A temperatura amolece o material, permitindo que ele se torne plástico, enquanto a pressão fornece a força motriz para fechar os vazios internos.

Consolidando Pós

Um dos usos mais comuns da HIP é na metalurgia do pó. Um pó metálico é selado em um recipiente moldado como a peça final. Durante o ciclo HIP, a pressão colapsa o recipiente e consolida o pó em uma peça sólida totalmente densa com propriedades que muitas vezes correspondem ou excedem as de materiais forjados.

Curando Defeitos Internos

A HIP também é amplamente utilizada como um processo de "cura" para peças feitas por outros métodos, como fundição ou fabricação aditiva (impressão 3D). A pressão externa fecha a porosidade de gás interna, a microcontração e os vazios, melhorando drasticamente a vida à fadiga e a ductilidade.

Compreendendo as Compensações e Limitações

Embora poderosa, a HIP não é uma solução universal. Sua aplicação envolve custos significativos e considerações de processo que devem ser ponderadas em relação aos seus benefícios.

Altos Custos de Capital e Operacionais

Os sistemas HIP são vasos de pressão especializados e caros que exigem infraestrutura significativa para manuseio de gás e segurança. Este alto custo de capital torna o processo mais caro do que os tratamentos térmicos convencionais.

Longos Tempos de Ciclo

Um ciclo HIP típico, incluindo aquecimento, manutenção de temperatura e pressão, e resfriamento, pode levar muitas horas. Essa natureza de processamento em lote pode ser um gargalo em ambientes de produção de alto volume.

Restrições de Tamanho do Componente

O tamanho da peça que pode ser tratada é limitado pelas dimensões internas da "zona quente" do vaso HIP. Embora existam unidades HIP muito grandes, elas são raras e extremamente caras de operar.

Requer uma Superfície Selada

Para curar defeitos em uma peça existente, a porosidade interna não deve estar conectada à superfície. Se um vazio estiver aberto para o exterior, a pressão dentro e fora do vazio se igualará, e ele não colapsará.

A Evolução Além de Seu Propósito Original

De sua aplicação nuclear de nicho, a HIP tornou-se um processo indispensável para a fabricação dos componentes mais exigentes em várias indústrias de alta tecnologia.

Superligas Aeroespaciais

A HIP tornou-se essencial para a indústria aeroespacial na década de 1970. É usada para eliminar a porosidade em componentes de superligas à base de níquel fundidas, como pás de turbina de motores a jato, garantindo que possam suportar temperaturas e tensões extremas.

Implantes Médicos

O processo é fundamental para a produção de implantes médicos de alta resistência e resistência à fadiga, como quadris e joelhos artificiais. Ele consolida pós de titânio ou cromo-cobalto em peças finais duráveis e biocompatíveis.

Fabricação Aditiva (Impressão 3D)

Mais recentemente, a HIP tornou-se uma etapa vital de pós-processamento para a impressão 3D de metais. Ela remove a porosidade inerente frequentemente encontrada em peças impressas, transformando-as em componentes totalmente densos adequados para aplicações críticas de suporte de carga.

Quando Considerar a Prensagem Isostática a Quente

A decisão de usar a HIP deve ser impulsionada por um requisito de desempenho claro que outros processos não conseguem atender.

- Se seu foco principal é alcançar a máxima integridade do material: Use HIP para curar vazios internos em peças fundidas críticas, melhorando drasticamente a vida à fadiga e a confiabilidade mecânica.

- Se seu foco principal é produzir peças de metalurgia do pó de alto desempenho: Use HIP para consolidar pós metálicos em um componente totalmente denso, de forma quase final, com propriedades equivalentes a materiais trabalhados.

- Se seu foco principal é qualificar metal impresso em 3D para uso crítico: Aplique HIP como uma etapa crucial de pós-processamento para remover defeitos internos e garantir que a peça atenda a rigorosos padrões aeroespaciais ou médicos.

- Se seu foco principal é criar componentes multimateriais inseparáveis: Aproveite a força original da HIP na soldagem por difusão para criar uma ligação metalúrgica perfeita entre materiais dissimilares.

Em última análise, a Prensagem Isostática a Quente é a ferramenta definitiva para alcançar a densidade máxima teórica e o desempenho contido em seus materiais avançados.

Tabela Resumo:

| Marco Principal | Ano | Aplicação Principal |

|---|---|---|

| Invenção Formal no Battelle Memorial Institute | 1955 | Soldagem por difusão para elementos de combustível nuclear |

| Adoção pela Indústria Aeroespacial | Década de 1970 | Eliminação de porosidade em peças fundidas de superligas (ex: pás de turbina) |

| Crítico para Implantes Médicos | Década de 1980+ | Consolidação de pós de titânio/cromo-cobalto |

| Vital para a Fabricação Aditiva | Década de 2000+ | Pós-processamento para curar defeitos em peças metálicas impressas em 3D |

Pronto para desbloquear todo o potencial de seus materiais com a Prensagem Isostática a Quente?

A KINTEK é especializada no fornecimento de equipamentos de laboratório avançados e consumíveis, incluindo soluções para teste e processamento de materiais que complementam a tecnologia HIP. Se você atua em P&D, aeroespacial, fabricação de dispositivos médicos ou fabricação aditiva, nossa experiência pode ajudá-lo a alcançar densidade e desempenho superiores do material.

Entre em contato com nossos especialistas hoje mesmo através do nosso Formulário de Contato para discutir como a KINTEK pode apoiar as necessidades específicas do seu laboratório e impulsionar suas inovações.

Guia Visual

Produtos relacionados

- Prensa Isostática a Quente WIP Estação de Trabalho 300Mpa para Aplicações de Alta Pressão

- Prensa Isostática a Quente para Pesquisa de Baterias de Estado Sólido

- Máquina de Prensagem Hidráulica Manual de Alta Temperatura com Placas Aquecidas para Laboratório

- Máquina de Prensagem Hidráulica Aquecida Automática com Placas Aquecidas para Prensagem a Quente de Laboratório

- Máquina de Prensa Hidráulica Automática de Alta Temperatura com Placas Aquecidas para Laboratório

As pessoas também perguntam

- Qual é o significado da Prensagem Isostática a Quente? Alcance 100% de Densidade e Integridade Superior do Material

- Qual é o propósito de usar 160 MPa de pressão em HIP para Inconel 718? Alcançar Densidade de Liga de Grau Aeroespacial

- Por que o Prensagem Isostática a Quente (HIP) é Necessário para Inconel 718 Fabricado Aditivamente? Alcance 100% de Densidade Teórica

- Qual é o princípio de funcionamento da prensagem isostática a quente? Desbloqueie Densidade e Desempenho Superiores de Materiais

- Como a Prensagem Isostática a Quente (HIP) aprimora as propriedades do CuNiCoZnAlTi? Alcançando Densidade Teórica e Resistência Máxima

- Por que as Prensas Isostáticas a Quente (WIP) são necessárias para baterias de estado sólido? Alcançar contato em nível atômico

- Como funciona a prensagem isostática a quente? Alcance Densidade Total e Desempenho Superior do Material

- Quais são as condições para a prensagem isostática a quente? Desbloqueie a Densidade Máxima do Material