Introduction: Definition and Basic Principles of Electrolytic Cells

Electrolytic cells are devices that utilize an electric current to induce a non-spontaneous chemical reaction. They are essential in various fields, including industrial processes, energy storage, and research applications. The fundamental principle of electrolytic cells is based on the transfer of electrons between the anode and cathode through an electrolyte solution. The anode is positively charged and oxidizes the electrolyte, while the cathode is negatively charged and reduces the electrolyte. The movement of ions through the electrolyte allows for the completion of the circuit. By understanding the principles of electrolytic cells, researchers can develop advanced techniques to enhance their functionality and optimize their use in cutting-edge lab research.

Table of Contents

- Introduction: Definition and Basic Principles of Electrolytic Cells

- Applications: Industrial and Research Applications of Electrolytic Cells

- Electrodes: Role of electrodes in electrolysis and battery operation

- Challenges: Limitations and Obstacles in Current Electrolytic Cell Techniques

- Advanced Techniques: Description of Advanced Characterization and AI Techniques

- Solid-State Electrolytes: The potential of solid-state electrolytes for all-solid batteries

- Conclusion: Future Implications and Potential Breakthroughs

Applications: Industrial and Research Applications of Electrolytic Cells

Electrolytic cells have a wide range of applications in both industrial and research settings. These cells are used to create new materials, analyze the chemical composition of a substance, and to study the properties of materials at the atomic and molecular levels.

Industrial Applications

One of the most important applications of electrolytic cells is in the manufacturing industry. Electrolytic cells are used to produce a wide range of materials, including metals, plastics, and chemicals. These cells are used to create new materials that have unique properties, such as strength, durability, and resistance to corrosion. Electrolytic cells are also used to create new catalysts that are used in industrial processes, such as the production of fertilizers and plastics.

Extraction and Refining of Metals

Electrolytic cells are used in the extraction and refining of metals such as copper, zinc, and lead. Most high-purity aluminum, copper, zinc, and lead are produced industrially in electrolytic cells. The anode is made of the extracted metal, and pure metal is deposited at the cathode. The electrolyte is made of the metal solution, such as copper sulphate and nickel chloride.

Electroplating

Electroplating is another important application of electrolytic cells. This process involves covering the articles made up of cheap metals by a thin covering of precious metal such as iron with nickel, chromium, silver, or gold. Electroplating is done for protection of metals against corrosion, giving shiny appearance to articles, giving reflecting properties to reflectors, and replacing work-out material.

Production of Chemicals

Electrolytic cells are also used in the production of chemicals such as caustic soda (NaOH), chlorine gas, potassium permanganate, hydrogen, and oxygen on a large scale.

Research Applications

In laboratory research, electrolytic cells are used to study the properties of materials at the atomic and molecular levels. Researchers use these cells to create new materials, analyze the chemical composition of a substance, and to study the behavior of materials under different conditions. Electrolytic cells are also used to study the behavior of biological materials, such as proteins and DNA.

Electrolysis

Electrolytic cells are often used to decompose chemical compounds in a process called electrolysis. Important examples of electrolysis are the decomposition of water into hydrogen and oxygen, and bauxite into aluminum and other chemicals. Electrolysis is a technique that uses a direct electric current (DC).

In conclusion, electrolytic cells have a wide range of applications in both industrial and research settings. These cells are used in the manufacturing industry to produce a wide range of materials, and in laboratory research to study the properties of materials at the atomic and molecular levels.

Electrodes: Role of electrodes in electrolysis and battery operation

Electrolytic cells are used in a variety of laboratory applications, and their functionality relies on electrodes. Electrodes can be made of different materials, such as metals, graphite, or carbon. Their role is crucial in electrolysis and battery operation.

Electrodes in Electrolysis

In electrolysis, electrodes are responsible for conducting electricity through the electrolyte solution, which causes a chemical reaction to occur. This reaction can either produce or consume energy, depending on the nature of the material being electrolyzed. During the process, an electric current is sent into and out of an electrolyte and into the solution to restore the flow of ions compulsory to run an otherwise non-spontaneous reaction. Electrodes are immersed and separated at a distance. A direct current [DC] supplied by the power source drives the reaction causing ions in the electrolyte to be attracted toward the oppositely charged electrode, Cathode, and Anode.

Electrodes in Battery Operation

In battery operation, electrodes are used to store and release energy through a chemical reaction, which is then converted into electrical energy. The electrodes are positively and negatively charged, and their polarity determines the flow of electrons in the circuit. When the battery is connected to a circuit, a chemical reaction occurs on the surface of the electrodes, which releases electrons. The electrons then flow through the circuit to power a device or charge a battery.

Anode and Cathode in Electrochemical Cells

Anode and cathode are the two electrodes used in all electrochemical cells, including batteries and electrolytic cells. The anode is the electrode through which the conventional current enters from the electrical circuit of an electrochemical cell (battery) into the non-metallic cell. The cathode is the positive electrode, meaning the electrons flow from the electrical circuit through the cathode into the non-metallic part of the electrochemical cell.

Conduction within an Electrolytic Cell

Current passes around the external circuit to and from the battery in the normal way, i.e., by the movement of electrons. However, in the cell itself, there is a very different process occurring. Positive ions from the electrolyte pick up electrons at the cathode and use them to perform the reduction of the ion. At the same time, negative ions migrate to the positive electrode (anode) to drop off electrons and get oxidized. The net effect is as if electrons are jumping from one electrode to the other.

In conclusion, the role of electrodes in electrolysis and battery operation is crucial. Electrodes are responsible for conducting electricity through the electrolyte solution, which causes a chemical reaction to occur. In battery operation, electrodes are used to store and release energy through a chemical reaction, which is then converted into electrical energy. Anode and cathode are the two electrodes used in all electrochemical cells, including batteries and electrolytic cells.

Challenges: Limitations and Obstacles in Current Electrolytic Cell Techniques

Advanced electrolytic cell techniques have opened up new possibilities for laboratory research, but they are not without their limitations and challenges. Here are some of the main obstacles that researchers face when using these techniques:

Limited Availability of Suitable Electrode Materials

One of the main challenges in advanced electrolytic cell techniques is finding suitable materials for the electrodes. The electrodes must be able to withstand high temperatures and corrosive environments, and finding materials that meet these requirements can be difficult.

Contamination of Electrolyte Solution

Another challenge is the potential for contamination of the electrolyte solution, which can affect the accuracy and reproducibility of results. Researchers must take precautions to ensure that the electrolyte solution is free from impurities that can interfere with the reaction.

Consistency of Current Flow

Maintaining a stable and consistent current flow through the electrolytic cell can be challenging, particularly when dealing with complex materials. Any fluctuations in current can affect the reaction and the quality of the results.

Time-consuming and Requires High Level of Expertise

Electrolytic cell techniques can be time-consuming and require a high level of expertise, which can limit their accessibility to researchers with limited training or resources. Researchers must invest significant time and resources in optimizing the reaction conditions and ensuring that the results are accurate and reproducible.

Despite these challenges, advanced electrolytic cell techniques hold great promise for cutting-edge laboratory research, and continued development and refinement of these techniques will be crucial for advancing scientific understanding in a wide range of fields.

Advanced Techniques: Description of Advanced Characterization and AI Techniques

Advanced electrolytic cell techniques have revolutionized laboratory research by providing a wealth of new information about the properties of materials. Electrolytic cells use electrical energy to drive chemical reactions, and they are an essential tool for scientists who study materials at the molecular level.

Advanced Characterization Techniques

Advanced characterization techniques such as X-ray diffraction, electron microscopy, and spectroscopy have greatly expanded our ability to analyze the structure and properties of materials. X-ray diffraction is a technique that enables researchers to determine the crystal structure of materials, while electron microscopy provides high-resolution images of the surface and internal structure of materials. Spectroscopy is a technique that enables researchers to study the interaction between light and matter, providing information about the molecular structure and properties of materials. These advanced characterization techniques have enabled scientists to gain a deeper understanding of the behavior of materials under different conditions.

Artificial Intelligence Techniques

In addition, the use of artificial intelligence (AI) techniques has allowed researchers to analyze vast amounts of data generated by these techniques and to identify patterns and correlations that would be difficult or impossible to detect by human analysis alone. AI enables researchers to develop models and simulations that can predict the behavior of materials under different conditions, and to identify new materials with novel properties.

AI has been used to optimize the performance of lithium-ion batteries by predicting the behavior of materials used in the battery's electrodes, electrolyte, and separator. AI has also been used to develop new catalysts for chemical reactions, such as the conversion of carbon dioxide to useful chemicals or fuels.

The combination of advanced characterization techniques and AI has led to the development of new materials with novel properties, such as materials that can convert waste heat into electricity or materials that can absorb carbon dioxide.

In the future, these techniques are likely to become even more powerful as researchers continue to refine them and develop new applications. Overall, advanced electrolytic cell techniques are an essential tool for cutting-edge lab research, and they are helping to drive innovation and discovery in a wide range of fields.

Solid-State Electrolytes: The potential of solid-state electrolytes for all-solid batteries

Solid-state electrolytes have emerged as a promising alternative to traditional liquid electrolytes in battery technology due to their increased safety, higher energy density, and longer lifespan. They can be used to create all-solid-state batteries that are more efficient and environmentally friendly than traditional batteries.

Advantages of Solid-State Electrolytes

Solid-state electrolytes have several advantages over liquid electrolytes. Firstly, they offer higher energy density due to their ability to store more ions in the same volume. Secondly, they are more stable than liquid electrolytes, which makes them safer to use. Thirdly, they have a longer lifespan than liquid electrolytes due to their ability to resist degradation over time.

Promising Candidates

Researchers are exploring a range of solid-state electrolyte materials to determine their performance and suitability for various applications. Some of the most promising candidates include lithium-ion conductors, sulfide-based electrolytes, and ceramics.

Lithium-ion conductors have been extensively studied and show great promise for use in solid-state electrolytes. They are able to conduct lithium ions efficiently, which makes them a good candidate for use in lithium-ion batteries.

Sulfide-based electrolytes are another promising candidate for use in solid-state batteries. They offer high ionic conductivity, which makes them ideal for use in high-performance batteries.

Ceramics are also being explored as a solid-state electrolyte material. They offer high ionic conductivity and excellent stability, making them a good candidate for use in high-temperature applications.

Challenges

Despite the many advantages of solid-state electrolytes, there are still several challenges that need to be addressed. One challenge is the difficulty in processing and manufacturing solid-state electrolytes. Another challenge is the limited availability and high cost of some of the materials used in solid-state electrolytes.

Conclusion

In conclusion, solid-state electrolytes have great potential for use in all-solid batteries due to their increased safety, higher energy density, and longer lifespan. Researchers are exploring a range of solid-state electrolyte materials to determine their performance and suitability for various applications. Despite the challenges, the development of solid-state electrolytes is a promising area of research that has the potential to revolutionize battery technology.

Conclusion: Future Implications and Potential Breakthroughs

As the research on advanced electrolytic cell techniques continues to evolve, the future implications and potential breakthroughs are promising. These techniques can improve the efficiency of industrial processes and lead to the development of new materials and technologies. The use of solid-state electrolytes in all-solid batteries can also revolutionize the energy storage industry. Moreover, the integration of advanced characterization and AI techniques can help researchers gain a better understanding of the underlying mechanisms of electrolytic cells. With further advancements, the possibilities for cutting-edge lab research using electrolytic cells are endless.

Produtos relacionados

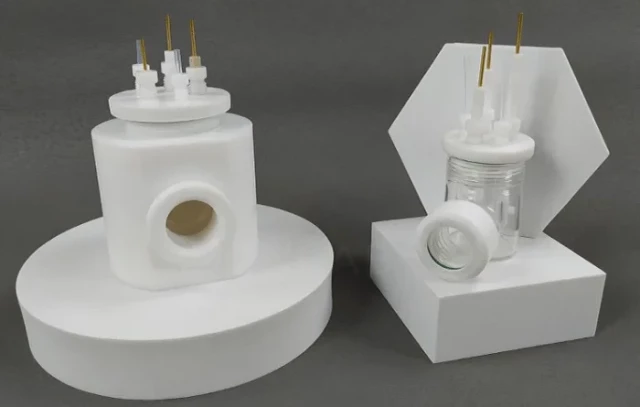

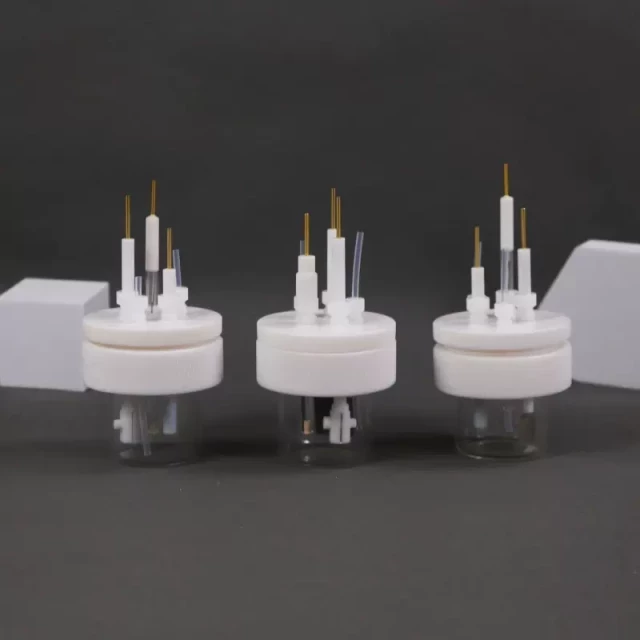

- Célula Eletrolítica Eletroquímica para Avaliação de Revestimentos

- Banho de Água de Célula Eletroquímica Eletrolítica Multifuncional Camada Única Dupla Camada

- Célula Eletroquímica de Eletrólise Espectral de Camada Fina

- Célula Eletrolítica Eletroquímica de Corrosão Plana

- Célula Eletroquímica Eletrolítica de Quartzo para Experimentos Eletroquímicos

Artigos relacionados

- Compreender as Células Electrolíticas de Corrosão Plana: Aplicações, mecanismos e técnicas de prevenção

- A Arquitetura da Precisão: Por Que os Detalhes Invisíveis Definem o Sucesso Eletroquímico

- Medidores de espessura de revestimento portáteis: Medição precisa para galvanoplastia e revestimentos industriais

- O Frágil Recipiente da Verdade: Um Manifesto de Manutenção para Células Eletrolíticas

- O Coração de Vidro: Por Que a Boa Ciência Morre em Células Sujas